|

Do-it-yourself

Microscope Conversion to LED-Light created by Frank Weithöner |

This instruction shows how to convert a standard microscope with light bulb to LED light. Only a cheap mobile phone charge can be used as the power supply because of the much lower power consumption of the LED light. Defective original power supplies do not have to be repaired or exchanged. Because a LED does not break, light bulbs are no longer needed.

The whole LED system costs less than 20 €.

The idea behind

In our workshop we often encounter problems with broken power supplies of microscopes. The power supplies are usually switch mode power supplies that can not be repaired easily. To supply the light bulb with an external standard power supply is an alternative but such power supplies which deliver 2 A (at 12 V) or even 4 A (at 6 V) are either not available or too expensive, and a dim function is still missing...

In other cases the bulbs were blown and these often very special bulbs are not available.

In the past these microscopes could not be repaired. But now we convert these microscopes to LED illumination. That works perfectly.

White ultra-bright LEDs, especially with a lens, are as bright as common 20 W-bulbs, but they only need a fraction of the current. The current needed is so small that common mobile phone chargers can be used as a power supply. Mobile phone chargers are very cheap and commonly available.

Advantages

The conversion to LED light brings some interesting advantages:

• The light is very bright.

A 1 W-LED in combination with a lens is as bright as a conventional 20W-light bulb.

• The light is real white.

Light bulbs produce a yellowish light which has to corrected by a blue filter. LED light is

real white and also does not change the colour when dimming.

• LEDs last for ever. No spare bulbs are needed any more.

The life expectancy of LEDs is about some ten thousand hours. They are also insensitive

against shocks and vibrations.

• The power consumption is much lower.

The power consumption is so low that cheap power supplies can be used.

• Microscope can run with batteries for hours.

A small (rechargeable) battery pack can provide power for some working hours.

Sometimes the battery pack can even be integrated in the microscope.

• Microscope and LED gets less warm.

Less power consumption also means less heat. The microscope does not get warm any

more.

• The conversion is cheaper than a repair of a power supply.

The whole system with power supply can be build for less than 20 €.

Disadvantages

I admit a white high-power-LED is not (yet) available everywhere. But because they are universal in the usage and only one model fits for all microscope types (and for other purposes) it make sense to order some pieces from Europe or US. In Europe a 1 W-LED with integrated lens costs about 10 €.

Considerations

After testing different LED types in different microscopes I came to the following conclusion:

Ultra-bright LEDs are available in standard 5 mm housings (No.1). Six to twelve LEDs produce a light which is bright enough (No.2). But the illumination with just six LEDs could be more homogeneous. The beam angle is not perfect but acceptable. One LED costs

0.20 - 1 €.

Beside the standard LEDs there are Luxeon high power LEDs (No.3).

1 W, 3 W and even 5 W-types exist. The LED is mounted on a small PCB with an aluminium board. The aluminium acts as a heat sink. This make mounting and cooling easy. The beam angle is 110°. An additional optic has to be used. Such LEDs cost 5 - 10 €.

A LED (or LED combination) of one 1 W is enough. The beam angle should be no more than 15°. 10° are perfect.

For me the best solution is the Luxeon Star/O (No.4). It is a 1 W-LED with an intergrated lens of 10°. The price is about 10 €.

|

1 super bright LED in standard 5 mm housing 2 first try with 6 x 5 mm LEDs 3 Luxeon 1 W high power LED 4 Luxeon Star/O with optic |

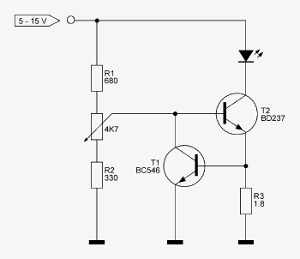

The electronic circuit

The LEDs can not connected directly to an external power supply. An electronic control is needed.

LEDs are controlled by the current and not by the voltage. The current has to be stable and the voltage will be adjusted automatic. This current stabilizer must run with any common mobile phone chargers. That means a wide-range voltage input of 5 - 15 V is demanded. The mobile phone charger has to deliver 400 mA which is always the case.

The specifications of a Luxeon LED are: 350 mA at 3.42 V. The needed electronics has to stabilize the output current to 350 mA whatever the input voltage is. The circuit is quite simple but tricky.

|

The circuit diagram. T1 and T2 make the current stabilizer. The voltage divider around the pot reduces the bias for T2 in order to dim the LED down. Because the LED current is stabilized the supply voltage is uncritical. Every mobile phone charger can be used. |

Transistor T2 controls the LED. Together with R3 it is in series with the LED. That means that the LED current also flows through the transistor and the resistor. Parallel to the resistor is the BE path of the transistor T1. Because the BE-voltage drop of a transistor is always 0.7 V also the voltage across the resistor is fixed to 0.7 V. But when the voltage across the resistor is fixed and the resistor anyway then also the current through the resistor must be fixed. The current is stabilized.

The value of the current depends on resistor R3.

R3 = 0.7 V / 0.35 A R3 = 2 Ω

After testing in practice I chose 1.8 Ω.

The power loss of the resistor is almost 1/4 Watt.

P = 0.7 V x 0.35 A P = 0.245 W

In theory a 1/4 Watt resistor is OK but it will get hot. With a 1/2 Watt resistor we are on the safe side.

The bias voltage for T2 is created by the voltage divider R1, the pot and R2. The values are uncritical because the current is already limited. R2 is responsible for the lowest brightness and ensures that the pot has a nice variation range.

T1 is a universal low power transistor of type BC 546 or similar.

T2 must be a bigger one. The size of T2 depends on the voltage drop across CE. It is the difference between the power supply voltage and the LED voltage (3.42 V) and the 0.7 V voltage drop across R3. T2 has to be bigger, the higher the power supply voltage is.

V(CE) = V(in) - V(LED) - V(R3)

The transistor voltage drop V(CE) multiplied by the LED current makes the transistor power loss. Current and power loss have to be considered when choosing the transistor type.

A BD 139 for example is big enough. I took the even bigger BD 243 just because it was lying around.

A small heat sink is never wrong. In this case mounting T2 directly to the housing of the microscope is even a better idea. The heat can be conducted away over the housing and the other devices can be mounted directly to the transistor. No PC Board is needed.

|

When using a heat sink or the metal housing of the microscope be sure that the transistor is mounted insulated by using a glimmer

insulator. Usually the metal part of the transistor is connected to the collector. But in our circuit the collector

is not connected to the ground. Make sure that also the screw is insulated from the transistor. |

Mechanical preparations

The original lens with the lamp housing is still needed. The LED will be mounted directly on the bottom plate. Make sure that the LED is placed exactly there, where the filament of the light bulb was before.

The blue filter disk is not needed any more. It can be taken out of the lamp housing.

|

Base of the microscope. The stand with the mechanic and the optics is removed. The lens housing with the lens is seen in the centre. At the right is the new pot for dimming and below the lens housing a small toggle switch for on/off can be seen. A combined pot/switch would be nicer but was not available. |

|

View to the base from the inside. Pot and switch are already mounted but not wired. For the transistor a nice place was found. An existing hole with a threat could be used. The paint from the surface of the microscope housing was removed before mounting. The transistor now has a smooth and plane thermal connection. |

|

The microscope gets an power supply socket at the back (up). The wiring is finished. Only the LED has to be mounted on the bottom plate. The parts are mounted directly at the transistor and at the pot. A PCB is not needed. |

|

A detailed view to the wiring. Make sure that T2 is insulated from the metal housing. Also use thermal paste for mounting. When the mechanical work is finished the wiring takes only 15 minutes. A closer look |

Experiences

All users where very satisfied with the conversion. I never heard a complain about the light. It seems that a 1 W-LED with a focus lens is really enough for all examinations. Even with the 100x oil-objective which is used for malaria examination the brightness is not only high enough but it is even brighter than the original illumination.

|

Update 2015 |

The 700 mA version

Five years have passed since I wrote the above article. In the meantime the LEDs got cheaper and more powerful. So I decided to upgrade the microscope illumination with a more powerful LED. The result is a microscope illumination with a 700 mA LED, which is twice as much as before. The power supply now is a 5 V USB power supply. As an example, here the conversion of an Olympus CH-2.

|

|

|

|

Differences to the 350 mW version

The LED is similar to the 1 W version. The voltage is the same, but the current now is 700 mA instead of 350 mA. The lens is also identical.

The circuit diagram of the current stabilizer remains the same. Only the value of resistor R3 has to be changed due to the higher current. Also a heat sink for T2 and the LED is advisable now.

The calculation for the new version is easy. The LED voltage is the same (≈3.4 V) but the LED current is twice as much. That means, also the current through T2 and R3 will be two-times bigger. Because the voltage drop across R3 is still 0.7 V, the resistor itself has to be two-times smaller then. That is easy to do, I simply take two of the resistors I still have in parallel. That halves the resistance and doubles the wattage, what is also necessary.

The BD237 as T2 is still fine (2 A) but I took a BD243 (6 A) just because I have many of them. This time the transistor definitely needs a heat sink because the power loss across the transistor is twice as much and it gets really warm.

|

The original wire potentiometer is removed and the new one is mounted in the same place so that the original dial can be used.

The user will not feel a difference. The mounting plate is also used as a heat sink for T2. |

This applies in particular to the LED. An LED does not get hot as a halogen bulb but still there is quite some heat that has to be conducted away. Make a test run. When the heat sink gets so hot that you can not touch it any more, take a bigger one. Do not forget the mounting insulation and thermal paste.

I took quite a big transistor heat sink. That is bigger than needed but in case of the Olympus it fits perfectly and later alignments of the LED were not necessary.

|

The new LED needs a proper heat sink. The measurements for the bore holes have to be made very carefully and precise in order to make sure that the focus is in really in the centre. A simple brightness test as described below can be very helpful. |

In the end you have to take anyway a heatsink or a piece of metal which fits into your microscope and positions the LED perfectly. Therefore some metalwork will be probably necessary. Make a test with the heatsink in place before you drill the holes for the fixing screws.

The power supply

To keep the power loss small, the input voltage has to be as small as possible. 5 V or 6 V are perfect. The power loss is small and T2 has still 'margin' to control.

The heat (power loss) across T2 depends on the voltage drop of CE. If we use a 5 V power supply the voltage drop is just 1.6 V (5 V-3.4 VLED). Multiplied by the current of 700 mA makes just 1.1 W of heat.

But if you would use a 12 V power supply the power loss of the transistor increases to 9.6 W!

This time I used a 5 V USB power supply which I installed in the microscope housing.

Testing

|

A simple way of measuring changes in the brightness: A LDR glued on a microscope slide. |

At the end a brief comment on testing the brightness.

I do not have a measurement instrument for the brightness. But what I have is a LDR which I glued with epoxy glue in the centre of a microscope slide and connected it to an ohmmeter. With this method I do not get an absolute measurement value of the brightness but I can see changes and can compare values. That is enough to align the LED and compare the brightness with the original microscope lamp.

So, my non-scientific measurement result in case of the Olympus CH-2 is: Wow! It's much, much brighter than the original...

Sources and additional information

Frank's transistor data list

www.luxeonstar.com

|

|