You can read the revised article in the book:

You can read the revised article in the book: Introduction to Medical Equipment Repair The book also contains a chapter on preventive maintenance, with recommendations on how to perform the various tests. Click here for more information. |

Laboratory Centrifuges |

by Frank Weithöner |

A centrifuge is a motor-driven equipment which is used in hospital laboratories. A centrifuge prepares body liquids from a patient for further examinations.

For diagnosing diseases, the examination of the components of body liquids like blood and urine are important. Each component has a specific use in the body and therefore a different test is required. But before particles of body fluids can be examined they first have to be extracted from the supporting fluid. This is what the centrifuge does. The liquid samples are spun around at high speed, which causes large centrifugation forces and consequently the substances separate due to their different densities. The separated components can then be examined.

Types and applications

Laboratory centrifuges differ in size, sample capacity, speed and application. First we distinguish between preparative and analytical centrifuges.Most centrifuges are preparative centrifuges. Their task is to separate the solids of a biological sample from the supporting fluid for further examinations.

Analytical centrifuges do both, extracting the components and doing an analysis at the same time. The analysis result is already given after centrifugation.

In hospital laboratories we mostly find small tabletop centrifuges. These centrifuges are called general purpose centrifuges, micro centrifuges or preparative centrifuges. They are used for separating cells, parasites and bacteria from body fluids like blood and urine.

The micro centrifuge

The micro centrifuge is a small compact bench top centrifuge. They are designed for micro tubes of 0.2 ml to 2.0 ml size. Sometimes they can also be converted into a hematocrit centrifuge when a special rotor is mounted to hold the required capillary tubes.Micro centrifuges are also available in refrigerated versions.

The maximum speed of a typical micro centrifuge ranges between 13,000 rpm and 15,000 rpm which corresponds to a gravitational force (g-force) of 16,000 g to 20,000 g.

Micro centrifuges which reach up to 35,000 rpm are also called high speed centrifuges.

The ultra-centrifuge

The ultra-centrifuge are capable of speeds of 100,000 rpm. This speed can only be reached when the rotor spins in a vacuum and the centrifuge furthermore is cooled.The forces on the samples in an ultra-centrifuge can reach up to 2,000,000 g.

The hematocrit centrifuge

Hematocrit centrifuges are analytical centrifuges. The working principle is the same but the samples are much smaller. Thin capillary tubes contain only a small amount of blood so that the forces are relatively low. At the end of a centrifugation the capillary tubes show already the results and no further analysis is needed. The so-called hematocrit value is the volume percentage of red blood cells in a sample.The speed of hematocrit centrifuges ranges from 7,000 rpm to 15,000 rpm.

The blood bank centrifuge

Blood banks also use centrifuges to centrifuge the blood bags with the 'whole blood' (WB) from the donors. The blood bags contain 300 ml to 500 ml of blood and thus these centrifuges are big and heavy stationary ones which are also refrigerated.Blood bank centrifuges spin with a speed of 4,000 rpm to 6,000 rpm.

Hand driven manual centrifuges

The usage of hand driven centrifuges is not without danger because the tubes spin open without a housing that protects the user. They also produce aerosol from the sample when open tubes are used (danger of infection). They are not recommended and even prohibited in some countries.Design of centrifuges

The centrifuge consists of a motor, a holder for the tubes which is called rotor and some control electronics.|

Note: In the following the term rotor stands for the sample holder

and not for the anchor, the rotating part of an electric motor. |

Fast rotation generates heat due to the friction of the spinning rotor with the surrounding air. This is unacceptable in cases when the samples are temperature-sensitive. For these situations a refrigerated centrifuge is needed. The cooling unit is similar to the one of a refrigerator and it will not be further discussed here.

Rotor and sample holder

Three different types of rotors are found in centrifuges: Swing-out

Swing-outA metal arm holds four or six buckets which swing outwards to a horizontal position during centrifugation. The tubes are carried in these buckets by means of adapters. Several tubes can fit into one bucket. Swing-out centrifuges are made for low speed applications.

The sample tubes are held in a solid rotor at a fixed angle, usually between 20° and 45°. Fixed angle centrifuges are general purpose centrifuges. They are faster and less expensive than swing-out types.

Vertical

VerticalThe tubes are also held in a solid rotor but at vertical position. Vertical rotors are used in ultra-high speed centrifuges. Special designed tubes are needed.

Tubes

Centrifuge tubes are small cylindrical containers that hold the sample liquid. Tubes are made of glass or plastic, round-bottomed or conical shape and usually come with an integral snap cap. Few plastic tubes (e.g. made of polypropylene) are autoclavable at 121°C but generally plastic tubes are disposable. Glass tubes are reusable, easier to clean and autoclavable, but break easier and are more expensive. Round-bottomed tubes are more robust than conical ones.

Tubes can vary in size from 0.2 ml to 15 ml

Tubes have to fit in their holders or buckets. Glass tubes in a swing-out rotor break when they are too long.

When tubes are filled with sample liquid it has to be done equally and then placed in the rotor symmetrically. This is important. Otherwise the centrifuge gets imbalanced, would wobble and damage to the motor and bearings would be the consequence. Tubes in fixed rotors should also not be overfilled because the liquid 'move' up the tube wall during spinning.

Capillary tubes of hematocrit centrifuges do not need to be balanced, only loaded symmetrically. They contain only a small amount of blood so that the forces are relatively low.

The physical working principle

After some time, the particles from a suspension settle at the bottom of the liquid. This process is called sedimentation. The driving force of sedimentation is gravity. The sedimentation process can be accelerated by centrifugation.The rotation motion of a centrifuge generates a centrifugal force which forces the substances of the suspension against the walls of the container. Particles with different density settle at different speeds and get separated as a result.

The centrifugal force is higher, the bigger the radius and the higher the speed of rotation. The density of the particles in the liquid determines the rate of sedimentation. Dense particles settle first, lighter particles later.

The Medical Laboratory Scientists have precise requirements for the sedimentation of their samples concerning the g-force. In order to find the correct speed setting for the centrifuge they have to calculate the speed according the following formula:

RCF = relative centrifugal force or g-force (g) r = radius, from the centre of the spindle to the bottom of the tube (mm) N = rotational speed (rpm) |

The relative centrifugal force or the speed can also be determined with the help of a nomogram (download).

Some manufacturers also offer an online calculator. This is the easiest way to calculate the speed or the force. link

Using the centrifuge

Not only the laboratory personnel need to know the correct usage of the centrifuge but also the hospital technician. During the repair and later while making a test run after a repair the technician has to know all the functions of the centrifuge in order to test them.|

Important: When you are not familiar with the equipment and not sure about

the correct usage read the user manual first. |

Use only accessories and tubes which are designed for your type of centrifuge.

Use only accessories and tubes which are designed for your type of centrifuge. Before using the centrifuge, make sure the rotor is tightened.

Before using the centrifuge, make sure the rotor is tightened.  Check the tubes for cracks before inserting them into the rotor.

Check the tubes for cracks before inserting them into the rotor. Samples should be closed with a cap before centrifugation.

Samples should be closed with a cap before centrifugation. The rotor has to be balanced at all times. Therefore, the rotor has to be filled with tubes

The rotor has to be balanced at all times. Therefore, the rotor has to be filled with tubes symmetrically. A tube with exactly the same weight/volume has to be put into the

opposing hole of the rotor. If there is an odd number of samples, prepare one additional

sample with water.

Do not open the lid while the rotor is still spinning (for all simple centrifuges without a

Do not open the lid while the rotor is still spinning (for all simple centrifuges without a safety lock).

Switch off the centrifuge immediately if it makes abnormal sounds or starts shaking or

Switch off the centrifuge immediately if it makes abnormal sounds or starts shaking or wobbling.

After a sample spillage clean the rotor and the buckets immediately with a mild multi-

After a sample spillage clean the rotor and the buckets immediately with a mild multi-purpose cleaner. See ↓Cleaning.

User manual

User manuals are always delivered with the centrifuge. I strongly recommend copying or scanning the manual before leaving it with the user. The copy should be kept together with other technical manuals in the hospital workshop.If the manual is missing, you are probably able to download it from the manufacturer's website. If this is not possible, try it here

Cleaning during usage

Cleaning of the centrifuge is in the first place the task of the user. The laboratory assistant has to ensure that the centrifuge is clean and operational at all times.But cleaning a centrifuge is also one part of the maintenance and repair procedure. Unlike other hospital equipment the cleaning of a dirty centrifuge should be done before starting with the service. The dirt could come from infectious samples and we should avoid getting in contact with it. Therefore it is recommended to wear rubber gloves when removing a filthy rotor and when washing the parts.

Cleaning of the inside of the centrifuge, the buckets and the adapters should be done by the user frequently or at least on a monthly basis, and of course immediately after a sample spillage. It is the task of the hospital technicians to introduce the laboratory personnel to the correct cleaning procedure.

Remove all tube adapters from the buckets.

Remove all tube adapters from the buckets. Wash buckets and adaptors in warm soap water. Mild multi-purpose cleaner or

Wash buckets and adaptors in warm soap water. Mild multi-purpose cleaner or dish-washing liquid are well suited.

Use a sponge and a plastic brush. Metal brushes scratch the surface, which create

Use a sponge and a plastic brush. Metal brushes scratch the surface, which create problems with corrosion in the future.

Only use kitchen scouring pads in extreme cases. But watch out, do not scratch the

Only use kitchen scouring pads in extreme cases. But watch out, do not scratch the surfaces.

For persistent dirt, leave the parts in the water to soak over night.

For persistent dirt, leave the parts in the water to soak over night.  After cleaning, rinse in clear water.

After cleaning, rinse in clear water. Disinfect the rotor bowl and buckets before servicing. Use only disinfectants

Disinfect the rotor bowl and buckets before servicing. Use only disinfectants recommended by the manufacturer.

Do not use alcohol or acetone.

Do not use alcohol or acetone. Do not leave parts to soak in disinfection solutions.

Do not leave parts to soak in disinfection solutions. Allow all parts to dry completely.

Allow all parts to dry completely.  Reassemble all parts and check if buckets move freely.

Reassemble all parts and check if buckets move freely.|

Attention: After a spillage or a broken glass tube the centrifuge has to be

cleaned, dried and disinfected immediately. The sample could be infectious. |

Installation

A centrifuge has to be placed on a solid bench or table. The surface must be plane and

A centrifuge has to be placed on a solid bench or table. The surface must be plane and exactly horizontal. No other equipment like microscopes and laboratory balances must

be placed close to the centrifuge because the centrifuge creates vibrations and an

electromagnetic field. As with any other laboratory equipment, the centrifuge should not

be exposed to direct sunlight.

Small table top centrifuges just need a suitable wall socket with a standard fuse

Small table top centrifuges just need a suitable wall socket with a standard fuse protection. Very big refrigerated centrifuges might need a three-phase power supply.

If the centrifuge is electronically controlled, the wall socket should be protected against

If the centrifuge is electronically controlled, the wall socket should be protected against spikes and power surges. Talk to the operator if voltage fluctuations are a problem and

look how other lab equipments are protected.

After the installation, the centrifuge has to be explained to the operating personnel. Make

After the installation, the centrifuge has to be explained to the operating personnel. Make a test run (↓Test run) and demonstrate all functions, controls and safety features. Do not

forget to demonstrate the cleaning procedure.

Hand over the user manual. A copy of the manual stays in the workshop.

Hand over the user manual. A copy of the manual stays in the workshop. Finally, a handing-over-protocol has to be signed by the responsible laboratory person.

Finally, a handing-over-protocol has to be signed by the responsible laboratory person.Power supply problems

An unstable and fluctuating power supply with spikes and surges is common in many areas and creates failures of electronically controlled equipment.Some centrifuges are sensitive against voltage fluctuations, some are not. But all centrifuges should be protected against spikes and surges. This can be done by a protection device, available as a plug adapter for a single equipment or as a more powerful version that can protect the whole laboratory. This type usually also contains an over and under voltage protection.

As a minimum protection all equipment in countries with an unstable and 'dirty' grid should get an additional varistor in the power supply input. This protects reliably against spikes and surges on the grid. More information here.

In the event of a complete power outage the brake of the centrifuge will not work and so it can take a very long time until a spinning centrifuge comes to a complete stop. It is also possible that the lid remains locked. If this is unwanted, an additional UPS helps.

Centrifuge construction

Simple centrifuges consist just of a motor, an electromechanical timer and a brake.Better centrifuges are provided with a speed control. Speed control means both, adjusting a desired speed with a knob and keeping the set speed stable over the centrifugation time. This can be done by a small electronic control unit. When further safety features and an electronic timer instead of a mechanical one are wanted, the control gets a little more complex. Nowadays a little microprocessor does the managing of the sensors for speed, lid lock, imbalance, contains the timer function and controls the power amplifiers for the motor and the brake.

Motor

Most centrifuges run with a universal motor. That is a single-phase motor, where the stator's field winding and the rotor winding are connected in series through a commutator. The motor is called universal motor because it runs on both AC and DC.More about motors later in the (↓Repair) section.

Control unit

The control unit is the heart of the centrifuge, which receives the settings from the control knobs for the speed and the centrifugation time. Also the sensors for the actual speed, an open lid or an imbalanced load are connected here. The control board processes all this information and then controls the motor, the brake and the lid lock.

Power supply

Depending on the motor and its control we find three different power supplies for three different types of motors: Direct mains, no power supply, for AC motors

Direct mains, no power supply, for AC motors Mains but rectified by diodes for DC motors

Mains but rectified by diodes for DC motors Power supply for a low voltage DC motor

Power supply for a low voltage DC motorIn addition, the electronic control unit itself needs a small power supply, typically for 5 V or 12 V. It is just a small transformer, a rectifier and a stabiliser.

Speed sensor

The speed sensor is either a forked photoelectric sensor or a Hall-effect sensor.In the first case a slotted disk is mounted on the shaft of the motor. The disk turns through the forked photoelectric sensor. On one side of the fork the sensor contains a LED and on the opposite side a photo transistor. When the shaft turns, the slots create a pulsed output signal. The frequency of this signal is dependent on the speed. The higher the speed, the higher the frequency.

Here the forked photoelectric sensor and the disk in between

The output signal of a Hall-sensor is similar to the signal of a photoelectric sensor. But instead of a slotted disk a magnet is mounted on the shaft. A Hall-effect sensor responds to the magnetic field of this magnet. The output again is a square wave signal with a frequency depending on the speed.

It looks like a small transistor, but it is not. This is the hall sensor. The shaft with the magnet is removed.

Speed control

The speed control process happens in the control unit. The control unit does two things. First, it converts the square wave signal from the sensor and compares this with the set speed from the control panel and adjusts the voltage for the motor until the actual speed reaches the set value.The speed signal is also needed for activating the safety lock. As long as the sensor delivers a signal the control unit knows that the centrifuge is spinning and it keeps the lid locked.

Brake

When the centrifugation time is over the rotor slows down and comes to a complete stop after a few seconds. This is only possible if the motor is decelerated actively by a brake. The brake is nothing else but a resistor that bypasses the rotating motor. The rotating motor then acts as a generator and produces energy which is absorbed by the resistor. The 'generator' then runs under heavy load and slows down. The electrical energy is transformed in the resistor into heat. Because the generated power is quite big, the resistor also has to be big. Indeed it is the biggest resistor inside the centrifuge and it is easy to find. Sometimes it is mounted with some distance on the control board and sometimes somewhere else away from the board where it is better cooled by the surrounding air.

A control board with an external brake resistor

Timer

In the simplest case the timer is just a mechanical clock like an egg timer with an additional switch. In all other cases the timer is an integral part of the electronic control unit, which might make use of a microprocessor in the most modern centrifuges.Imbalance detector

An imbalance sensor detects an unbalanced rotor and lets the motor stop immediately. The sensor is nothing more than a micro switch which is attached close to the shaft. If the load is not balanced the shaft starts to wobble and finally touches the micro switch. The activated switch gives a signal to the control board which stops the motor.Lid sensor

For safety reasons it should not be possible to start the centrifuge when the lid is open. A micro switch mounted at the lock mechanism detects an open lid and passes this information to the control board.

The Solenoid of the safety interlock and the lid switch (blue)

Safety interlock

For safety reasons it is also important that the lid is locked during centrifugation. For this purpose a solenoid pushes a metal pin through the latch of the lid. The solenoid is activated by the control unit. The control unit gets the needed information from the speed sensor. Only when the speed sensor detects a standstill the solenoid gets activated and releases the lid. Please note that in practice this does not happen immediately but after a little delay time.Emergency lid lock release

In case of a malfunction or a total failure, all centrifuges have an emergency release for the lid.How that works is explained in the user manual. But in principle it is a similar procedure as opening a CD or DVD drive of a computer: In a little hole in the housing a pin or screwdriver has to be inserted which pushes back the lock mechanism. Make sure the centrifuge has stopped spinning and the power supply is disconnected before attempting to release the lid lock.

Some centrifuges keep the lid locked in case of a power outage. Then the user should know how the lid can be opened manually.

Refrigerator

When a centrifuge spins at extremely high speeds, the friction with the surrounding air creates heat. The samples would get warm and that would have negative influences on the samples. To avoid this, ultra-high speed centrifuges are refrigerated.The cooling unit is similar to the one from a refrigerator and is will not be further discussed here.

Maintenance

The maintenance procedures described here and in service manuals of the manufacturers are just recommendations and have to be adapted to the situation on site.The maintenance could be done on a half-year basis. The technician can do a function check, a thorough cleaning and a calibration when it is necessary and when the needed test equipment are available.

Preparations

Before you start with the maintenance read the user and the service manual of your

Before you start with the maintenance read the user and the service manual of your centrifuge.

Document all checks and measurement results in a maintenance report.

Document all checks and measurement results in a maintenance report.  Check the working place of the centrifuge in the laboratory. Is it solid, stable and clean?

Check the working place of the centrifuge in the laboratory. Is it solid, stable and clean? Is the power supply stable? If not, is at least the wall socket protected against spikes and

Is the power supply stable? If not, is at least the wall socket protected against spikes and surges? An over voltage protection would be even better.

Cleaning during maintenance

Clean and disinfect before starting to work on a centrifuge. Spilled samples might be contaminated.More under ↑Cleaning during usage.

Check from the outside

Make a visual check of the housing for cracks and for broken-off and missing parts. Are

Make a visual check of the housing for cracks and for broken-off and missing parts. Are the rubber feet OK?

Check all switches and controls if they function properly.

Check all switches and controls if they function properly. Check the power cord and plug for damages. Look for burned contacts and loose cables.

Check the power cord and plug for damages. Look for burned contacts and loose cables. Is the plug suitable? Replace or shorten the power cord when it is damaged. Pull the cable

to check the strain relief. Replace the AC plug when it is of the wrong type and does not

match the existing wall socket.

The lid has to close and lock easily. If problems occur, readjust the lid hinges or lock

The lid has to close and lock easily. If problems occur, readjust the lid hinges or lock assembly.

Check the lid gasket if there is one.

Check the lid gasket if there is one. Check the sample buckets, their carrier or the rotor for cracks and corrosion.

Check the sample buckets, their carrier or the rotor for cracks and corrosion. Check the rubber cushions in the buckets if they all are in place.

Check the rubber cushions in the buckets if they all are in place. Check that the rotor is not loose. The centre nut has to be tightened firmly.

Check that the rotor is not loose. The centre nut has to be tightened firmly.Test run

Make a test run without samples. Listen for any unusual noises.

Make a test run without samples. Listen for any unusual noises.  Check the speed adjustment, the timer and the brake function. When stopping the

Check the speed adjustment, the timer and the brake function. When stopping the centrifugation, the centrifuge should decelerate.

Try to open the lid while the centrifuge is still spinning - it should be not possible.

Try to open the lid while the centrifuge is still spinning - it should be not possible. Check the lid security switch. Try to switch on when the lid is open. This should also not

Check the lid security switch. Try to switch on when the lid is open. This should also not be possible.

Check from the inside

Make sure you have disconnected the power cable.

Make sure you have disconnected the power cable. Take off the unit housing.

Take off the unit housing. Look for spilled liquids and corrosion of the metal parts.

Look for spilled liquids and corrosion of the metal parts.  Take a close look at the circuit board. Examine the electronic components for burns,

Take a close look at the circuit board. Examine the electronic components for burns, breaks and leakages. Search the solder side of the board for cold soldering points and

disconnections.

Check relay contacts for burns. Clean the contacts with a fibre glass brush when the

Check relay contacts for burns. Clean the contacts with a fibre glass brush when the contacts got black.

Motor

Check the motor attachment. All screws have to be tight. Usually the motor is mounted in

Check the motor attachment. All screws have to be tight. Usually the motor is mounted in rubber buffers. Check the buffers for ruptures. Rubber buffers also become hard or

crumbly after some years.

Check the brushes and the commutator for wear. Take out the brushes and check the

Check the brushes and the commutator for wear. Take out the brushes and check the wear. The surface of the carbon brushes must be smooth and even and should shine

silvery. Replace them if they are less than half of their original length. A motor with new

brushes should run for a while without load and at low speed so that the brushes can get

shaped. This should be done later after reassembly of the centrifuge.

Check the bearings for clearance. Exchange them if necessary. The bearings are in

Check the bearings for clearance. Exchange them if necessary. The bearings are in principle always sealed so that they are permanently lubricated. Lubrication is not

needed, they are maintenance free.

Lubrication

In general lubrication means the use of grease. Apply a small amount of grease and move the joints or bearings. Wipe off unnecessary grease with a cloth afterwards. Use a cloth that you only use for greasy works or better use paper tissues.Avoid using oil. Oil washes out the grease. Use oil only in exceptional cases or when it is demanded in the service manual.

Lubrication areas include lid, hinges, lock mechanism, bucket carrier and sometimes bearings, if they are not sealed.

After the maintenance

Assemble the centrifuge and make a last visual check.

Assemble the centrifuge and make a last visual check. Make a test run under laboratory conditions. Therefore set back all the controls to the

Make a test run under laboratory conditions. Therefore set back all the controls to the user's settings.

Load the rotor with some tubes and run the centrifuge for 30 minutes.

Load the rotor with some tubes and run the centrifuge for 30 minutes. Finally fill out your maintenance log and put a new service sticker on the centrifuge

Finally fill out your maintenance log and put a new service sticker on the centrifuge showing the next maintenance date.

Performance test

When performance test results show deviations that cannot be remedied, it has to be noted clearly in the maintenance log. It is then up to the user to decide if the equipment has to be repaired or if the deviations are taken into consideration for future applications.Timer Accuracy

Check the timer against a stop watch, your watch or your mobile phone. The result should not vary by more than ±10 %. Adjust the timer if necessary and possible. Often it is enough to change the knob position of the timer.Speed Accuracy

For checking the speed a special tachometer is needed. These devices usually work with strobe light and will work on any centrifuge with a transparent lid or a clear port in the lid.Load the centrifuge with some tubes. Set the centrifuge to two or three speeds and compare the speeds with your tachometer.

If the measurements differ from the set speed, a calibration is needed. The calibration is done on the control board if a trim-pot exists. If there is no calibration for the speed, maybe there is one for the digital display. Consult the service manual for this adjustment.

For simple centrifuges without a digital display for the speed, you only have to change the knob position of the speed adjuster.

A tachometer is an optical measurement equipment. It needs to 'see' the rotating object

In remote regions a speed measurement may be dispensed. A tachometer is probably not available and the simple centrifuges which are mostly used there do not have a speed adjustment anyway. Negative effects caused by too high or too low speed could be compensated by extending or reducing the centrifugation time. Discuss this issue with the Biomedical Scientists of the hospital laboratory.

Temperature Accuracy

For checking the temperature accuracy of a refrigerated centrifuge a calibrated thermometer is needed. The probe should be placed close to the sensor of the centrifuge. Look up the position in the service manual if you do not find it. Close the lid and wait until the set temperature is reached. Compare the temperature with your reference thermometer. Calibrate the thermostat or the control electronic if the difference is bigger than ±3°C.Needed tools

Beside the normal tool set, cleaning material and a clean and bright workplace we will need the following equipment for the performance check: Stop watch.

Stop watch. You can also use your wrist watch or mobile phone.

Tachometer.

Tachometer.Modern handheld digital tachometers are not expensive. They are available for less than

50 $. These devices work with strobe light and will only work on centrifuges with a

transparent lid or a clear port in the lid. Tachometers do not have to be calibrated

because they are just counters. There is no internal calibrated reference which has an

influence on the accuracy of the measurement result. That's why in terms of accuracy a

cheap instrument is as good as an expensive one.

Thermometer.

Thermometer. A calibrated digital one with an external sensor is recommended. A multimeter with an

external probe is also fine, as long as both, sensor and multimeter fit together and this

set is calibrated.

Repair

Before you start with the repair: Read the user and the service manual of your centrifuge.

Read the user and the service manual of your centrifuge. Fill out a service record / job card with all equipment data and the fault description. Note

Fill out a service record / job card with all equipment data and the fault description. Note the accessories and cables.

Note also the user settings of the controls and switches.

Note also the user settings of the controls and switches. If the fault shall appear during the operation, make a test run and wait until the fault

If the fault shall appear during the operation, make a test run and wait until the fault occurs.

Make sure that the fault is really a defect and not just an operating error.

Make sure that the fault is really a defect and not just an operating error. |

Remember: Do not forget to bypass the lid switch when troubleshooting on an open centrifuge. |

|

Caution! Never attempt to stop a rotating motor with your hands or with a tool! |

Error code

In the case of a fault, a microprocessor controlled unit will show an error code in the display. With the help of the service manual the fault can be identified easily.Motors

The typical laboratory centrifuge is driven by a universal motor with a power rating between 100 W and 150 W. Rotor and field winding are connected in series through the commutator.Motors in centrifuges are usually quite robust. Problems with motors are not very common. It often has other reasons why a centrifuge does not rotate. It is more likely that the motor driver or simply the lid sensor is the error cause.

|

Caution! Always take off the rotor when working and testing on the motor or motor control. |

Bearings and shaft

The motor shaft turns in two ball bearings, one on each side of the motor. The bearings are in principle always sealed so that they are permanently lubricated. They are maintenance-free.When the motor makes grinding noises or the shaft has clearance the bearings should be replaced.

These sealed bearings are standard industry bearings which are available in every bigger town.

Keep in mind that worn ball bearings could be the result of wrong usage. Teach the user how to load the centrifuge correctly.

Windings

The field winding of the stator and the rotor winding can be checked easily with the ohmmeter. The rotor winding is expected to be in the range of a few ten Ohms at 230 V. The resistance of the stator should be 50 % more than at the rotor. 115 V motor versions will have a ¼ of these values.Please note that some motors have thermal fuses which are embedded between the windings of the stator. If they are blown, you measure an interrupted stator.

In case a winding is burnt or you measure a short circuit or an interruption, the winding has to be renewed. Rewinding of motors and transformers should be no problem. In every town you find small shops where one does rewinding of motors and transformer for little money.

Brushes

The carbon brushes of the universal motors which run on AC wear out much faster than on DC voltage. They burn down faster due to the heavy sparking around the carbon brushes. That is normal in AC operation and is the reason why often motors of centrifuges run on DC.Remove the carbon brushes from their holder and check their lengths. If they are less than half of the original length, they should be replaced. The surface of the carbon brushes must be smooth and even and should shine silvery.

If you need carbon brushes and you cannot get the original ones take oversized brushes and file them down to the right size. These universal carbon brushes you get in every bigger town.

|

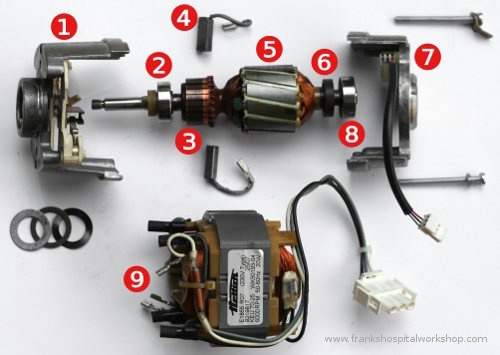

1 Stator housing with holder for carbon brushes 2 + 8 Bearing 3 Commutator 4 Carbon brushes |

5 Rotor coil 6 Magnet for the speed sensor 7 Stator housing with hall sensor 9 Stator with field coils |

Motor driver

The output signal of the control unit is too weak to control the motor directly. A driver stage with a power transistor is connected between the control and the motor. It is either a PWM control (Pulse-Width Modulation) in case of a low voltage DC motor, or a PFC (Phase-Fired Controller) for an AC motor. The focus of troubleshooting should be the power transistor/MOSFET/TRIAC of this stage. High voltages, high currents and big power losses stress these components a lot so that failures are common.To test the motor and the driver stage you can bypass the driver transistor/MOSFET of the PWM control or the TRIAC of a PFC control. The motor has to spin then with maximum speed. To bypass the driver transistor connect the collector with the emitter or in the case of a MOSFET, drain with source. But be careful, make sure that you do not take the base or gate connector. A TRIAC of a PFC can also be bypassed. Therefore connect the two anodes. If you are not sure about the pin connection check the data sheet of your type here.

|

Caution! TRIAC controls work with mains potential! Do not touch any components! |

If the motor just runs slow, check also the brake resistor. Disconnect it and start the centrifuge again.

Here is an example of a typical motor control of a micro centrifuge.

The motor is running on 230 VDC. In this case the AC side is regulated and then rectified. The TRIAC controls the AC-voltage to the motor. It gets the control signal via the optocoupler from the microprocessor. The optocoupler is needed to decouple the mains potential of the TRIAC from the potential-free low voltage of the rest of the control unit (which is not seen here). The regulated AC now gets rectified by the four diodes before it gets to the motor.

The brake circuit in this example is quite tricky because the brake relay is activated when the centrifuge does not brake and in standby mode the brake resistor (100 Ω in the above circuit) is connected across the motor. The advantage is, that in case of a power outage the relay would release, the resistor by-passes the motor and slows down the centrifuge.

When the centrifuge has been started the relay is activated, the contacts switches over and the motor is connected via the 1 Ω resistor (vertical) to the regulated power supply. The brake resistor then is by-passed by the relay. The 1 Ω resistor has no influence on the motor regulation or the brake function. The resistance is just too small. But it creates a small voltage drop depending on the current through it, which is the motor current. If the motor current gets too big due to a fault, the voltage drop across this resistor gets bigger and the centrifuge will switch off or slows down.

Left: Power supply input with a noise filter. Right: The four rectifier diodes of the power supply for the motor, the TRIAC (with heat sink) and the optocoupler to decouple the mains potential of this stage from the potential-free low voltage of the rest of the board.

Timer

Often with older centrifuges the electromechanical timer makes problems. These timers are simple clockworks with a bell and an additional electrical switch. The clockwork parts are cheaply made from thin metal and after a while the teeth of the gear wheels wear off. Repairing such a cheap mechanical timer is usually not possible. But of course a centrifuge can also run without a timer. Then the operator has to use a stop watch or an egg timer and has to switch off the centrifuge manually.

A typical mechanical timer without the housing. The gears are worn off. The timer is not repairable. Left the contact which switched off the unit after expiration of the set time.

But keep in mind, that you cannot simply bypass a defective timer if the centrifuge has a safety lock mechanism. In this case you have to exchange the timer for a normal switch. This will be the new start/stop switch.

If you only bypass the timer you will not be able to open the lid after switching on the centrifuge because the centrifuge will start spinning immediately, the control unit will notice the spinning motor and will lock the lid. And when you switch off the whole centrifuge after spinning also the control unit will not work any more and the motor will not be slowed down.

Rotor

It is not advisable to repair a cracked rotor. There are enormous forces acting on the rotor and therefore the rotor has to be perfectly balanced. But if you want to try then you should be very careful, start with an empty rotor and slow speed and be prepared to switch off immediately when the centrifuge starts to wobble.Brake

The brake resistor is often connected to the motor with a relay. Both relay and resistor can be the reason why the brake does not work. Often the brake resistor looks burned because of the intense heat it has to absorb, but usually it is not. If you want to check the resistor, the resistor is easy to find because it is the biggest one in the centrifuge. It has a low resistance (anything less than 200 Ω) and is easy to check with the ohmmeter.The function of the relay is audible and noticeable. Black relay contacts can be perfectly cleaned with fibre glass brush. Never file contacts. This destroys the surface of the contacts.

Brake resistor (white), relay (black) and driver transistor for the relay

Interlock

The interlock mechanism is built with a solenoid which pushes a metal pin through the latch of the lid. Often the solenoid mechanism or the latch of the

lid is bent and needs new adjustment.

The interlock mechanism is built with a solenoid which pushes a metal pin through the latch of the lid. Often the solenoid mechanism or the latch of the

lid is bent and needs new adjustment. When the interlock is not working at all, check the voltage across the solenoid. The solenoid also needs a switching transistor. Follow the cables to the main board and check the transistor.

Keep in mind that there is a delay time after the centrifuge has come to a standstill before the interlock opens.

Lid switch

A tricky source of trouble: When the lid switch is not exactly adjusted the centrifuge will not start. You should therefore not only focus on the motor and its driver when a centrifuge does not work, but also take a look at the lid switch.Speed sensor

The speed sensor is placed close to the motor shaft and is either a forked photoelectric sensor or a Hall-effect sensor.It usually has 3 cables: plus, minus and the control signal which is a square wave signal when the rotor turns. The supply voltage is probably 5 V and should be checked first. For checking the output signal you will need an oscilloscope. When you turn the shaft slowly by hand, then also a voltmeter will also work.

After the repair

When the centrifuge is repaired, assemble it and continue with a full maintenance as

When the centrifuge is repaired, assemble it and continue with a full maintenance as described under ↑Maintenance including a thorough cleaning.

Make a test run under laboratory conditions. Therefore set back all the controls to the

Make a test run under laboratory conditions. Therefore set back all the controls to the user's settings.

Load the rotor with some tubes and run the centrifuge for 30 minutes.

Load the rotor with some tubes and run the centrifuge for 30 minutes.  Finally fill out your job card/service report and put a new service sticker to the centrifuge

Finally fill out your job card/service report and put a new service sticker to the centrifuge showing the next maintenance date.

Before returning it to the laboratory, make sure the centrifuge is complete with all cables

Before returning it to the laboratory, make sure the centrifuge is complete with all cables and accessories.

Service manual

You find the correct repair and maintenance procedures in the service manual of the manufacturer. Unfortunately it is difficult to get the particular manual. While user manuals are always delivered with the new equipment, service manuals are never provided by the manufacturer. Also on the websites of the companies you will not find any service manual. The policy is clear, the companies want to do all repairs by themselves. Only a certified technician who took part in a special training for certain equipment gets a service manual and technical support.Nevertheless, I made the experience that it is worth to write a friendly email to the manufacturer when a service manual is needed. Most of the time I received an answer with the needed manual attached.

All the manuals I have collected, you can find here.

Spares

There is no need to keep special spare parts for centrifuges in stock. Sometimes a fuse is needed, but spare fuses should always be available in the workshop anyway.Life expectancy

Hospital centrifuges are in principle robust and durable. Low and high-speed centrifuges can easily be used for 10 years. But there is no reason why a quality laboratory centrifuge could not run for another 10 years if it is regularly maintained.Links and sources

Here are some Wikipedia Medical Equipment articles:Laboratory centrifuge

Ultracentrifuge

Universal motor

Pulse-width modulation"

Phase-fired controllers

You can read the revised article in the book:

You can read the revised article in the book: Introduction to Medical Equipment Repair The book also contains a chapter on preventive maintenance, with recommendations on how to perform the various tests. Click here for more information. |

|

|